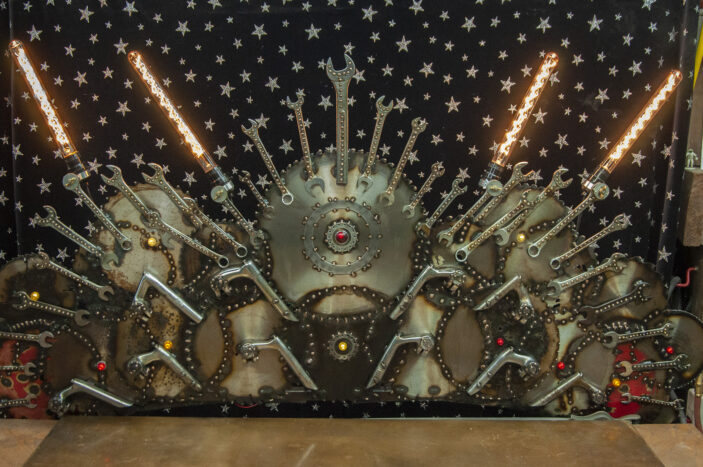

This is an image of my old studio space at the Artisan’s Asylum, taken a few years ago. When I first started making art at the Asylum, I didn’t actually have any art to show – I took all my work home so I could hang out with my new robot friends. Nonetheless, when the Asylum tour came by my space they would point at my unorganized piles of steel fodder and say “This is Skunk – he makes really cool robot sculptures.” The people on the tour would nod and then move on to more exciting parts of the makerspace.

I realized I should have a few examples of my work for people to see. The problem was that art made from industrial steel was camouflaged by the busy Asylum environment. Over the years I slowly built up my cubicle so that my robot sculptures had a place where they could stand out – an intimate hangout space, inspired by the inside of a traveling gypsy wagon or fortune teller’s room. As you can see in the above image, curtains can do a lot. There’s hundreds of pounds of carefully organized steel in the lower section, and even a small hidden office in the back. As far as I know it was the only fifty-square foot space at the Asylum to have a secret room.

A New Chapter

Due to the coronavirus there hasn’t been any tours since last March, and we’re planning to move to Allston this autumn. I’ve been ‘working for home’ with a small welder in the basement, so as a result the studio space has become quite dormant. Most of the metal that I typically use to make robots has already migrated, so all that was left was the larger pieces for big work, and the studio itself. I’ve been part of the Artisan’s Asylum community since before day one, when the founder asked if SCUL could be a part of his vision. I plan on keeping my membership and will continue my involvement through art, talks, and my bicycle chopper gang, but for now it makes sense to stop using my two studio spaces as storage depots.

There’s not too many folks at the Asylum nowadays, and I try to come by when things are slow, to do my best to help people stay safe. The people who did come by had melancholy feelings about the exodus, but I assured them that I plan on being a very active part of the Asylum community. Some call it ‘the end of an era’, but I’m calling it ‘the start of a new chapter’.

The Arch Gets a New Life

The archway that adorned the entrance was constructed in three separate pieces that bolt together, spanning seven feet. I couldn’t bear the thought of putting it in storage, so my brainstorming led me to the idea of putting it behind my makeshift weld bench. It was fairly easy to drill some new bolt holes to reconfigure the pieces so that it they layered more and therefore had less of an overall width. I cut up some angle iron from old bed frame to make a stand, and within a few hours I had an ornate back plate for my bench.

When the arch was up high, I wasn’t as concerned about the details, since it was made to be viewed at a distance. Now that it’s living at eye level I thought it was time to add the finishing touches. I capped all the stem holes with washers and fillister head machine screws, then added lots more bronze ‘charm rivets’. The novelty incandescent ten-inch bulbs are mounted using old clip lamps, minus the aluminum cones.

Here’s a detail image of the vintage open-ended wrenches and the bronze weld dots that I can’t seem to get enough of.

I made sure each tip of all the saw teeth were dulled with a weld bead. Some of the blades had carbide tips, which don’t respond well to being molten – but with a pulse of the torch they would soften up enough to fall off the tips of the blades. It was gratifying.

The arch used to have simple LED holiday string lights decorating it, which looked charming way up overhead, but unprofessional at close range, so I opted to use some of my precious vintage panel lights. Luckily the holes of the saw blades are the exact correct side for the lamp housings.

The center of the back plate is made up of a particularly large blade, which has a larger center hole. Another stroke of luck was that I had a larger sized vintage lamp that fit this one too. I often experience moments of serendipity such as these as I make my art. Perhaps it’s because so many of the components I use were made using the Imperial measurement system and not in millimeters.

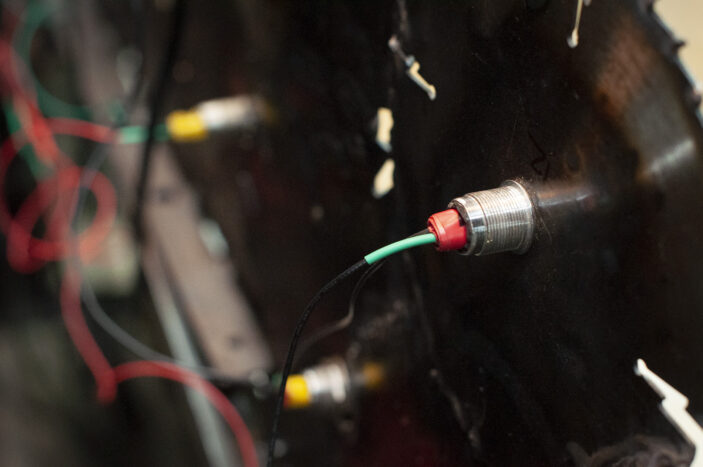

Lighting the vintage lamp housing was fairly easy, falling back on what I learned when making a big rocketship light up.

The layered pieces give the arch a little more depth, but still fit together nicely.

The Bench

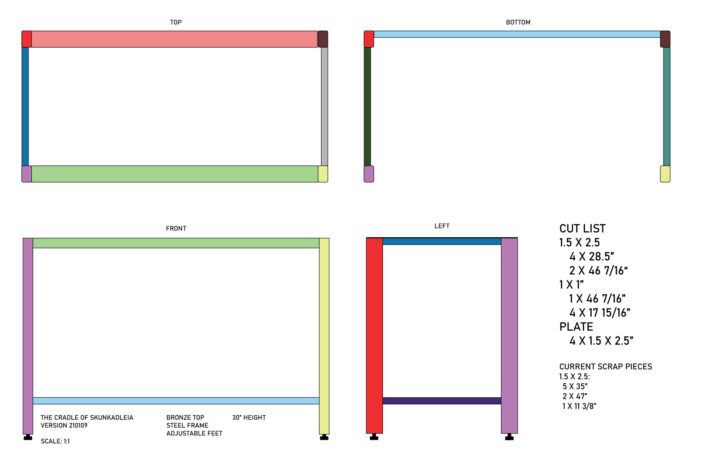

With such a grand back plate installed, my thoughts turned to the makeshift weld bench I had been using, which was merely a couple of aluminum plates screwed into a borrowed sturdy wooden bench. This was adequate for the low amperage TIG welding I was doing, but it was a far cry from a proper work area. I had hoarded some scrap steel that I found in the recycle bin years ago, which was perfect for a simple table.

About fifteen years ago a friend and fellow artist gave me her leftover bronze pieces from a large outdoor sculpture project. A bronze plate of this size and thickness is a kingly gift indeed! I’ve been using it as a desk top blotter on top of my home office table, but I decided it has found its true calling as the top of ‘The Cradle of Skunkadelia’. It only needed a frame worthy enough and sturdy enough to support it. I made my plans in Adobe Illustrator, as I’m not savvy in the ways of CAD software.

When it comes to weld benches, my needs are simple: a flat, level, unobstructed top on a sturdy frame. I color coded the pieces in my plans, as I was trying to figure out if I had enough scrap in the right lengths. If I made the side pieces and the lower cross piece out of 1 x 1 inch square stock, I had enough 2.5 x 1.5 inch rectangular pieces for the legs and the upper cross pieces. I think the proportions work nicely, as if it was purposeful and not cobbled together from things I had lying around.

I made my cuts at the Asylum with a horizontal band saw, took the pieces home, and sanded off most of the rust and paint marker, and cleaned the surfaces with acetone.

In order to keep the bench level as well as from wobbling, adjustable feet were needed. It’s particularly important my bench is level – when I make a standing robot, it needs to have its center-of-gravity squarely under its feet, or it may be prone to tipping over: in other words, working upon a tilted weld bench makes for tipsy robots.

My original plan was to use four pieces of plate cut to the size of the opening at the bottom of the feet, which would then have holes drilled and then a nut welded to it. In my search for some hardware that was strong, I came across these mighty bolts and nuts. They just so happen to be the perfect fit to the inside of the legs.

A gentle tap with my big hammer got them to settle into the right spot with enough room for a stalwart weld bead.

I don’t typically find myself making anything with right-angles so my tooling and fixturing is woefully lacking. I do have a sizeable square, which was essential, and the bronze table top was flatter than anything else I had in the shop, so in a way I used the table top to build the table. Talk about picking yourself up by your bootstraps!

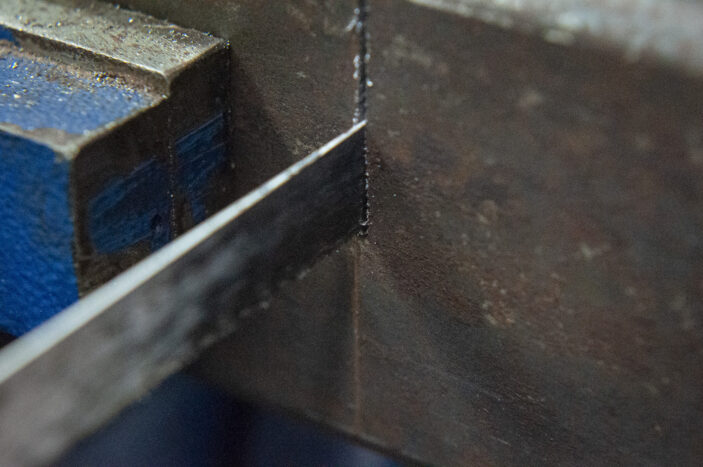

It’s very rare to have a project devoid of setbacks – turns out I miscalculated my cuts with the horizontal band saw and made the cross pieces too long. The above images shows by how long. To avoid the long trip to the bandsaw and back for just three cuts, I decided to prove my accuracy with a hack saw and try and make the three cuts freehand.

I’ve got enough experience with a hacksaw to know that a square cut is a challenge. It’s also a fair amount of work to cut through steel tubing of this thickness, but I’ve gotten pretty good a sawing with my left hand so that my right arm can get a bit of rest so I can perpetually hack saw for much longer. I’m proud to say that I was surgically careful enough to make near-perfect cuts on all three pieces. Note in the above photo I was even able to keep the kerf on the outside of the scribe. I was back in business!

Making the side pieces square and flat was reasonably easy, but the cross pieces were much more challenging, as I had to deal with more angles, awkward shapes, and it was starting to get heavy. Using the new adjustable feet I was able to raise the side pieces until they were level with the cross piece resting on the old weld bench. After checking with the square in all three orientations I made my tacks.

Once the whole table was tacked together, I took a big step backwards and eyed it from all angles. It’s important to not weld anything permanently until you have the whole structure put together, because un-welding things is a lot more labor-intensive than hitting control-z on a keyboard. Sure enough: the sides had a bit of a twist relative to one another. I fixed it by adjusting the feet so the table rocked on opposite legs, then put pressure on the shorter corners to force it into square by sitting on them. Unfortunately I neglected to take a picture, which I regret: I like to document the setbacks that inevitably occur, as well as how they are overcome. I broke a couple of tacks, but the table twisted into alignment within my tolerances. I added some new tacks, checked everything once more, then welded the tubes together. It felt pretty meta and a little poetic to be welding a welding table on a welding table.

I really wanted the bench to be as unadorned and simple as possible, but I need a proper place for the grounding clamp. While it’s possible to get the clamp to secure to the one-inch tubing, but it takes a lot of force to open the clamp a whole inch, and it’s a bit of a pain to do so while reaching under the bench.

I had this handmade engraving plate that I discovered in a scrap bit many years ago, which I’ve been keeping in a special drawer labeled ‘favorites’. I never could find a use for it even though I love it. I thought it would make a very nice secret touch for this special bench. Boy do I wish I could tell whoever made this that it found it’s way out of the scrap bin and into my heart!

I didn’t weld it too much in case I had second thoughts. I’m hoping the clamp holds tightly enough so that there’s no arc-outs on the engraving. I’m fairly confident it won’t be a problem.

Thanks to careful planning, and a little luck, the bronze plate fit nicely on the frame. Since the bronze is heavy, it wants to stay put, so some small tacks were all that was needed to affix it to the frame. I decided tiny welds on the side were better than drilling holes and bolting it down.

The Completed Pair

Here’s the completed Cradle of Skunkadelia. Total cost – zero dollars, if you don’t count money I spent on things I already had lying around. I had purchased the novelty bulbs and the sockets, the LEDs, the weld wire and the solder, but I think the rest was donated or trash picked. I’d like to think that I will make better art at a workstation like this – at the very least I will enjoy the view. It will certainly make a nice backdrop for photographing works-in-progress. And I still have the aluminum plate that I can use as a cover if I wind up welding anything that may damage the bronze.